New Zealand Made

Highest Quality and Local Support

Energy Efficient

Patented Heat Recovery System

Environmentally Friendly

Closed Loop Heat Pump Technology

Commercial Dehydrator Range

Buy a Rexmoi® dehydrator from $90,000 or rent from $166+gst /day.

Call to discuss the best option for your business.

Want to try before you buy?

Hire the Rexmoi factory for the day and get expert assistance to help you test the feasibility of your product.

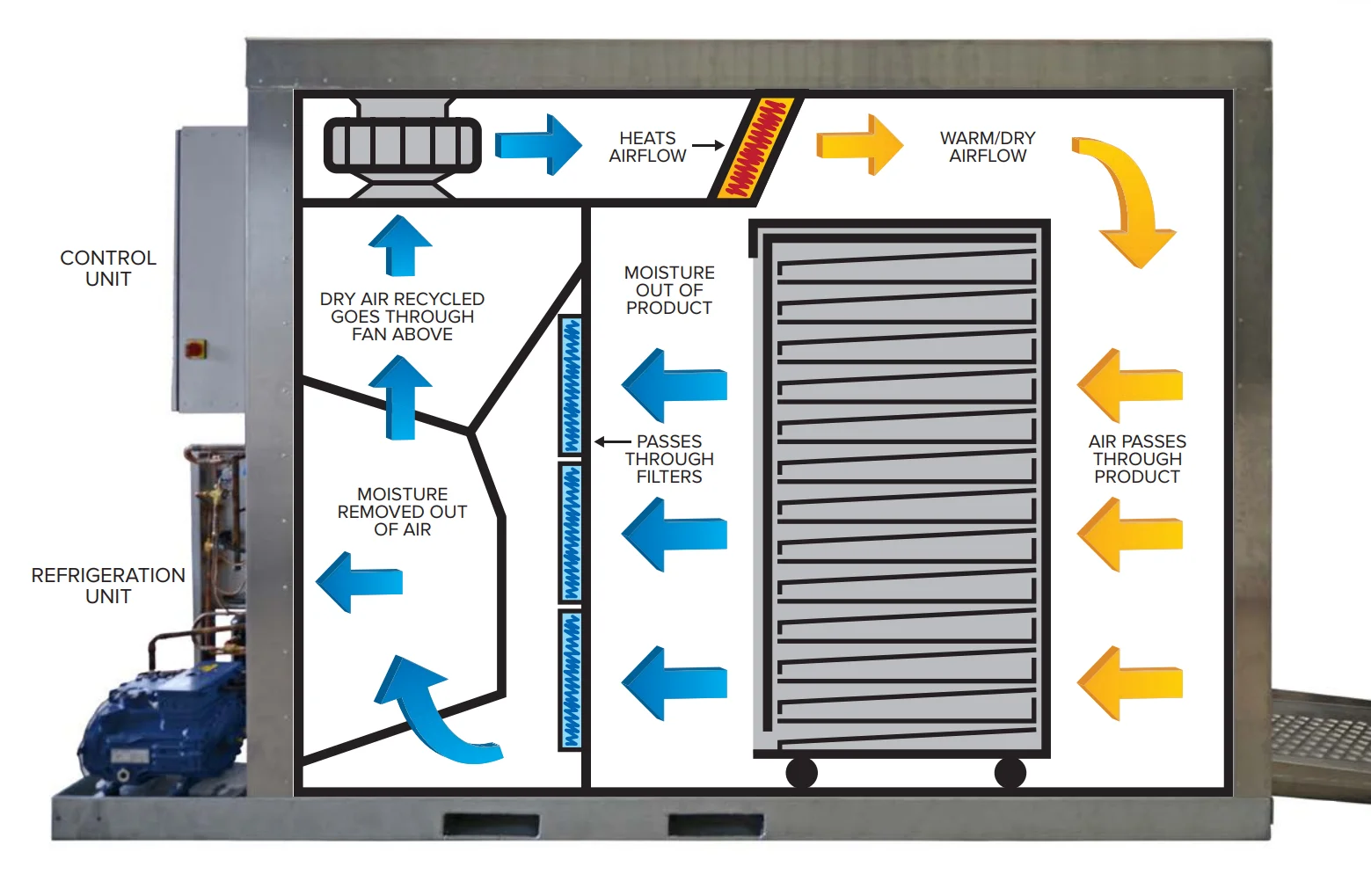

Learn MoreHow Rexmoi Closed-Loop Heat Pump Dehydrators Work

Heat pump dehydrators are energy-efficient drying systems that use heat pump technology to remove moisture from food or other materials. They operate using a closed-loop system that recycles heat, reducing energy consumption compared to conventional drying methods.

Advantages of NZ made Rexmoi Heat Pump Dehydrators:

✅ Energy Efficiency – Uses less energy by recycling heat.

✅ Lower Drying Temperatures – Preserves nutrients, flavors, and textures.

✅ Consistent Drying – Provides even, controlled drying conditions.

✅ Reduced Heat Damage – Suitable for sensitive products like fruits, herbs, and seafood.

Rexmoi are the only dryers in NZ to have Patented Run-around coils, these offer major advantages:

- Energy Recovery & Efficiency – Run-around coils (also called heat transfer coils) help preheat or precool the incoming air using waste heat from the outgoing air, improving overall system efficiency and reducing energy consumption.

- Enhanced Moisture Removal – By pre-cooling the air, heat transfer coils help in condensing moisture more effectively, improving the dehydration process.

- Reduced Compressor Load – Since the coils recover and transfer heat effectively, the compressor doesn’t have to work as hard, leading to lower operational costs and extended compressor life.

- Better Temperature Control – These coils help regulate temperature more precisely, preventing overheating or excessive drying, which could damage the product.

- Lower Operating Costs – By reducing the need for additional heating or cooling energy, heat transfer coils contribute to cost savings in the long run.

- Sustainable Operation – With improved heat recovery and lower energy consumption, the system becomes more environmentally friendly.

- Improved Air Quality & Consistency – The heat exchange process helps maintain stable conditions within the dehydrator, ensuring consistent drying results and product quality.

The Benefits of a Rexmoi Closed Loop Dehydrator

Very low running costs

Rexmoi® uses energy-efficient heat pump technology combined with Patented Run-Around coil technology, which removes moisture at up to 5 liters per Kw used.

Wide Temperature range, 10° - 70°C

The Rexmoi® Dehydration system can operate at lower temperatures, offering a wide temperature range from 10-70°C, lower drying temperatures retain the best colour and benefits of your products while maximising efficiency and productivity.

Environmentally Friendly

The Rexmoi® Dehydration System is Closed Loop. This means there is no contaminated air introduced, and no exhaust vents giving off unpleasant odours, which could be an issue for neighbours and local regulations.

Made in New Zealand

Support and training available throughout NZ, (and internationally via remote monitoring). All components are NZ sourced and readily available should servicing or repairs be required. We offer nationwide servicing.

Simple touch screen operation

Touch screen programmable with variable speed fans and compressors, providing extremely accurate temperature control down to 0.1°, the most accurate drying available.

Food grade stainless steel

Only food grade stainless steel is used for the interior of Rexmoi dryers.

Data Logging

Data logging meets government MPI regulations. Drying cycles are displayed in both numerical and graph forms.

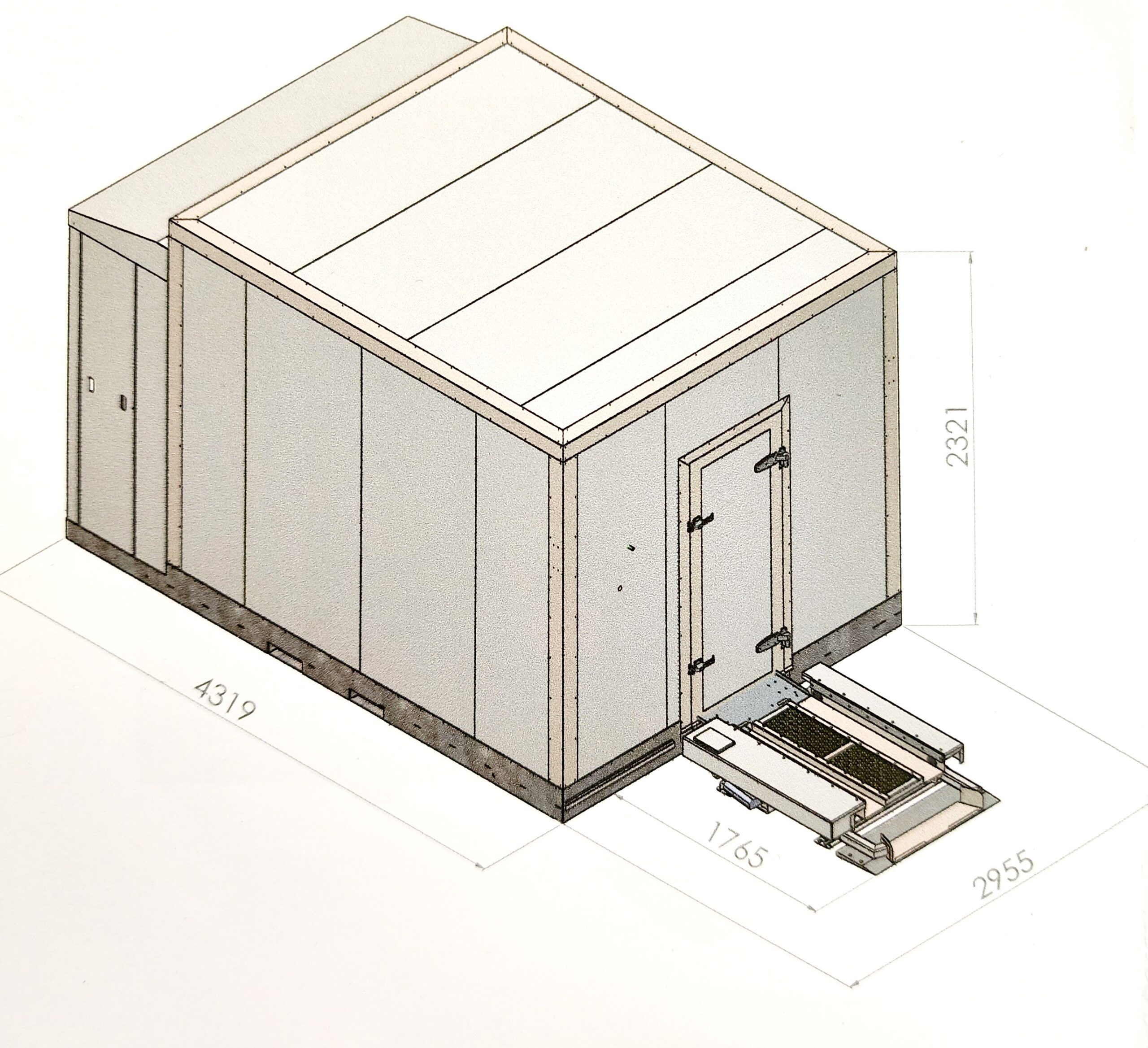

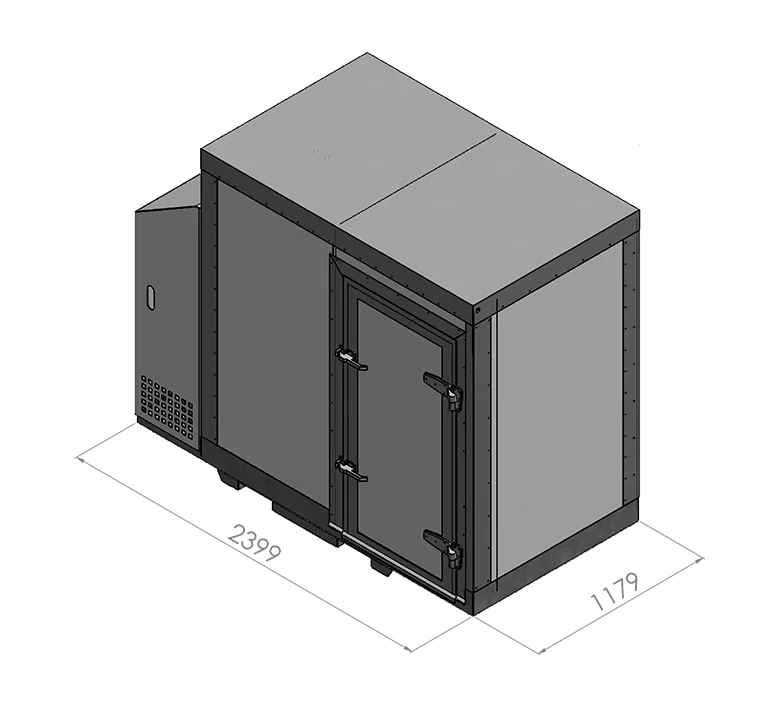

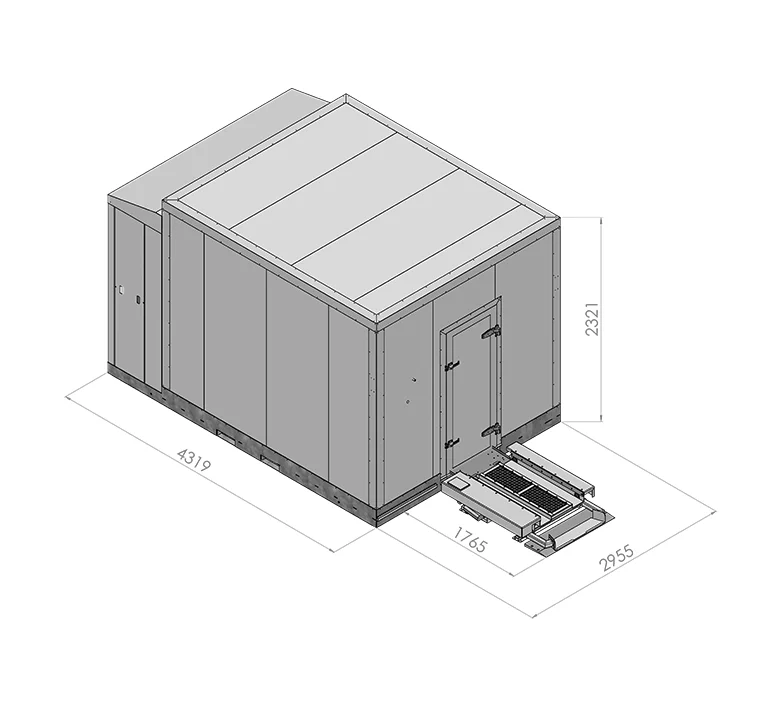

Easy to install or relocate

Rexmoi® dehydrators are easy to relocate with a forklift-friendly galvanised base.

Remote Monitoring

Remote monitoring option so you don’t need to be on-site, the dryer can run overnight and you can view the drying progress from home.

Program multiple drying recipes

Program multiple drying recipes for different products and modes of operation, including; bacterial kill stage, heating, dehumidifying, power cooling, fan-only cooling.