Frequently Asked Questions

What does the Rexmoi® Dehydrator do?

In Drying mode, our dehydrator and drying machine removes moisture from products

It can cool products at the end of the drying cycle

It can program a bacteria ‘kill stage’

It can be used for low-temperature cooking

It can operate as a chiller down to 4° C

Why use heat pump with Heat Transfer technology for dehydration?

Energy efficient – savings of up to 60% per year in energy costs

Low running costs – about half of standard hot air dryers or freeze dryers

No electric elements or naked flames (safety)

A sealed chamber means there are no odours vented out, and no contaminated air pulled in

Rexmoi® dehydrators can be opened anytime during the process to check the product.

Why the energy savings happen:

-

Closed-loop system: The heat pump recycles heat from the exhaust air rather than venting it.

-

Latent heat recovery: When moisture condenses out of the air, the latent heat is recovered and reused.

-

Efficient heating: The refrigerant cycle can deliver multiple units of heat for each unit of electricity.

Tip: Internet search using ChatGPT or other AI apps, which provide unbiased information, to better understand the substantial benefits of Heat Transfer coils, (also called Run-Around Coils) and Heat Pump technology for food drying.

Can I try before I hire or buy a dehydrator?

We offer a product testing unit for hire at $600 per day at our premises in Tauranga NZ. This will likely shorten the trial and error process considerably, saving you a lot of time and money. Or you can hire a dryer and have it delivered to your site for product testing and feasibility trials.

What can I use the Rexmoi® dehydrator for?

Removing moisture from products

Controlling moisture in products

Low temperature cooking

As a Chiller (can automatically chill products as low as 4° at the end of the drying cycle)

Do Rexmoi Dehydrators have an insulated floor?

Yes, Rexmoi dehydrators have built in floors. A fully insulated floor is essential for consistent drying results and energy saving.

Some commercial and industrial dehydrators do not have an insulated floor, this means the drying cycle first needs to heat up the concrete floor, this wastes a lot of energy and makes the drying cycle longer, this longer drying time also uses more energy.

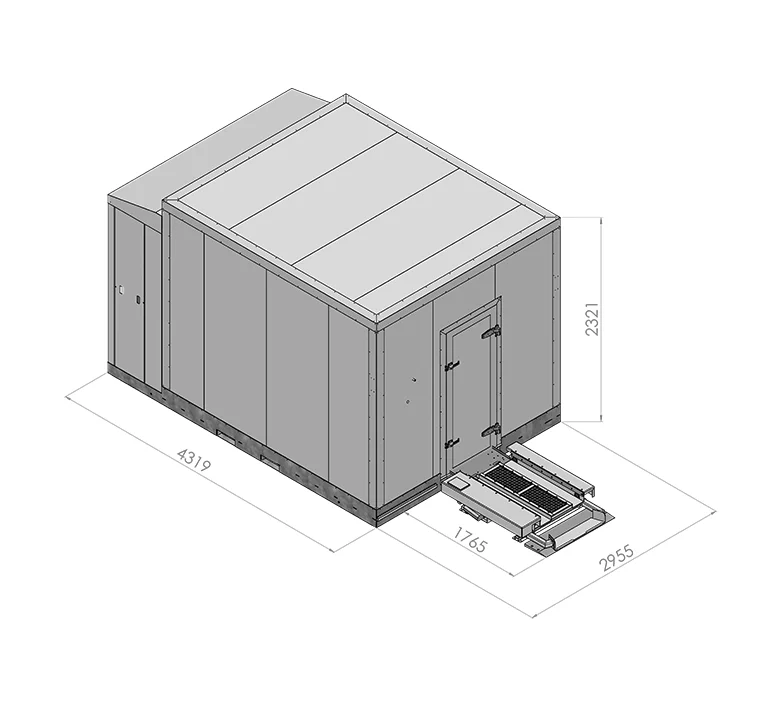

Rexmoi dehydrators are built forklift friendly with a steel base which makes them very easy to relocate should the need arise. Rexmoi dryer floors are fully insulated, resulting in lower running costs, and a quicker drying cycle which lowers labour costs.

What do I need to use the Rexmoi® dehydration system?

Single phase or three phase power – depending on the unit

Prefer inside or under cover, but can operate outside

What government incentives are available in NZ?

The New Zealand government is offering an incredible opportunity for forward-thinking business owners—claim a 20% tax return on your investment in new assets!

Here is what makes this incentive a game changer:

• Immediate Financial Relief: Immediate Financial Relief: Claim an immediate 20% tax deduction on your investment, reducing your taxable income and improving your bottom line this year.

• Enhanced Cash Flow: Reinvest your savings into further growth, be it hiring talent, expanding production, or launching innovative projects.

• Modernisation Opportunity: Upgrade to a state-of-the-art plant and

secure long-term operational efficiency.

Do not let this opportunity pass you by. Leverage the government’s commitment to driving business innovation and modernization—reap the rewards of a smart investment that brings both immediate and lasting value to your enterprise. Now is the time to act, upgrade your operations, and let every dollar work harder for you!

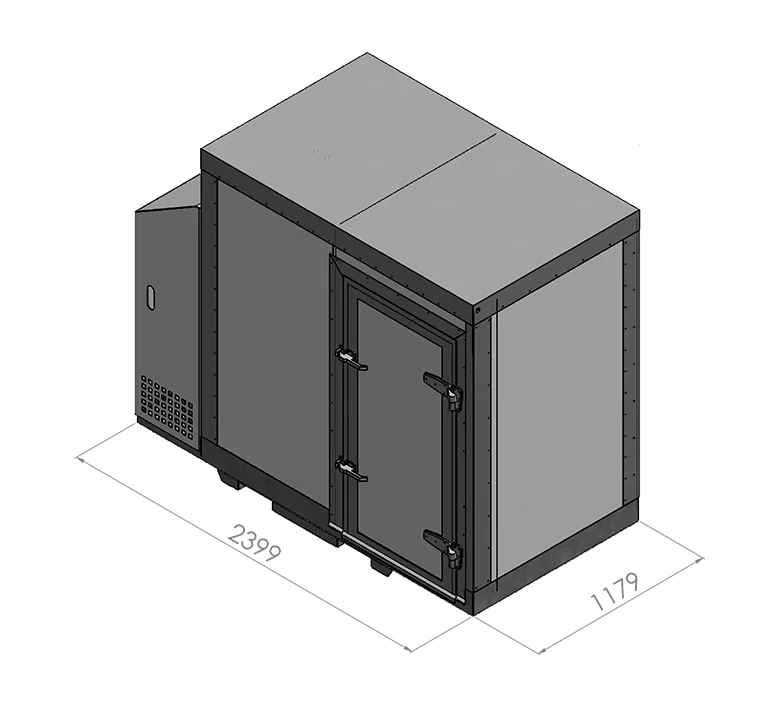

How big is the Rexmoi® dehydration unit?

View the specifications on the specific dryer model page you would like to rent or buy. Dryers can be loaded and moved into position with a forklift.

Heat Pump Drying vs Freeze Drying: Which is Better?

🔄 Heat Pump Drying vs ❄️ Freeze Drying: Which is Better?

When choosing the right drying technology, it’s important to balance speed, energy use, product quality, and cost. Here’s a clear comparison of heat pump closed-loop air drying and freeze drying:

🕒 Drying Time

-

Heat Pump Drying: 4–20 hours

-

Freeze Drying: 20–48+ hours

✅ Heat pump drying is significantly faster.

⚡ Energy Efficiency

-

Heat Pump Drying: Low energy use (heat is recovered and reused)

-

Freeze Drying: Very high energy consumption (vacuum and refrigeration systems)

✅ Heat pump drying is much more energy efficient.

🌿 Product Quality

-

Heat Pump Drying: Good shape, color, and nutrient retention

-

Freeze Drying: Excellent shape, color, and nutrient preservation

🔄 Freeze drying has the edge for sensitive products, but expensive.

💰 Cost & Complexity

-

Heat Pump Drying: Lower capital cost, simple operation, easy maintenance

-

Freeze Drying: High upfront cost, complex vacuum systems, larger footprint

✅ Heat pump systems are more cost-effective and easier to run.

Commercial Dehydrator Range

Rexmoi® dehydrators are priced from approximately $90,000 to $300,000 (or hire from $95+gst /day)

depending on the size and options your business requires. Call us now to discuss your options, we can also custom build to your requirements.

Want to try before you buy?

Hire the Rexmoi factory for the day and get expert assistance to help you test the feasibility of your product.

Learn More